Scope of Our

Shop Drawing Services

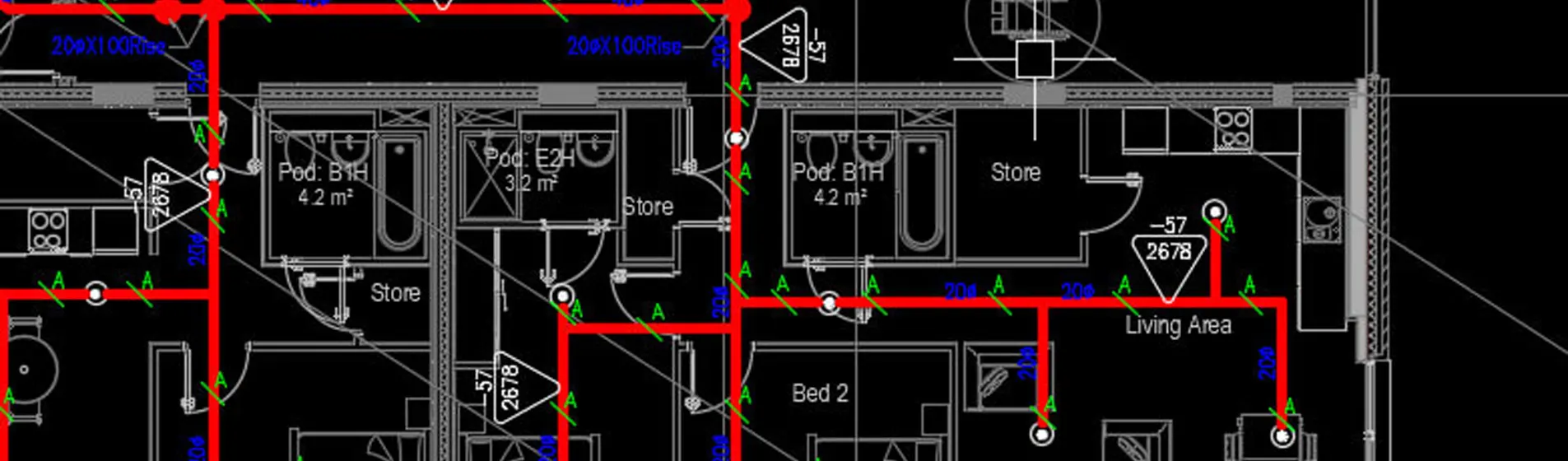

MEP Shop Drawings

We prepare coordinated MEP shop drawings for HVAC, piping, plumbing, electrical, and fire protection systems. Each drawing includes routing, sleeve and penetration details, hanger layouts, elevation details, Bottom of pipe, dimensions and equipment tagging aligned with architectural and structural grids. We generate these MEP shop drawings from coordinated Revit models and verified through clash detection to make sure on-site installation is accurate and faster for MEP contractors and general contractors.

Structural Shop Drawings

Our structural shop drawings cover steel, rebar, and precast concrete packages. We detail connection layouts, anchor bolt plans, weld symbols, and bending schedules for fabrication and erection. Each drawing adheres to project standards and is reviewed for dimensional accuracy, ensuring every component fits right the first time.

Architectural Shop Drawings

We produce architectural shop drawings for casework, millwork, doors and windows, partitions, ceilings, and façade systems. These drawings capture setting-out dimensions, joinery details, and coordination with MEP and structural elements. All sheets are formatted to client templates, ready for approval and fabrication.

Deliverables

Detailed Fabrication Information

Includes precise dimensions, tolerances, materials, finishes, and connection details needed for manufacturing. Shows exactly how each component will be fabricated and assembled on site.

Installation and Coordination Details

Provides layouts, anchorage points, and sequence of installation, coordinated plans, sections, elevation details for all trades.

Bill of Material

Includes list of all components, quantities, and part numbers, may include product spec sheet with reference to design standards or codes.

CAD/BIM Models

Deliver coordinated 2D CAD drawings, 3D BIM model (with approx LOD 400–500) including revision logs, drawings titles, sheet set up as per project standards.

Each deliverable is designed to support consultant approvals, fabrication, and on-site execution with minimal rework.

Our Shop Drawings Represent

Represents fabrication and assembly-ready details which are more accurate than construction documents.

Include project standards like title blocks, and sheet setup style.

Includes exact geometry, dimensions, materials, joints, and connections.

Used by fabricators, contractors, and manufacturers to create shop drawings and fabrication drawings.

Shows components as they will be built or installed in the field.

Shop-Drawing Workflow by Eagle BIM

Understanding Scope and Project Setup

We begin by reviewing the scope of work, design drawings, BIM Execution Plan (BEP), and client requirements. This includes understanding the required LOD (Level of Development 400), file formats, drawing standards, and submission timelines.

Clash Coordination

We develop or import base Revit/AutoCAD models to start the coordination process. Our team runs clash detection using tools like Navisworks or Revizto, or Revit interference check to identify conflicts between architectural, structural, MEP systems.

Shop Drawings Creation

We develop detailed shop drawing level details (LOD 400) 3D models with precise geometry, dimensions, tolerances, sleeves, penetration, spool drawings, Bill of material list, connections, and anchoring details. Our team prepares 2D sheets directly from the model, including plans, elevations, sections, and detailed views, along with installation layouts

Quality Check and Internal Review

Our produced shop drawings go through drafting quality checks for accuracy, scale, detailing, annotations and verify constructability, and compliance with project standards and client requirements.

Client Review and Final Deliverables

We share the package with clients for review and for approval, based on any feedback or markups, we update the model & drawings and share our final deliverables including PDF shop drawings, Revit (RVT) and DWG files. Bill of Materials (BOM) sheet, IFC or Navisworks file for coordination.

Why Choose Us

Value you can measure Coordinated drawings that cut RFIs and reduce field rework.

Experience and expertise Trade-specific teams for MEP, structural, and architectural packages.

Sector experience Delivered across commercial, residential, healthcare, education, industrial, hospitality, retail, and data centers.

Accuracy with flexibility Adapts to project standards, client templates, and codes without losing precision.

Client-first approach Clear communication, predictable timelines, and full transparency through each phase.

Industries

Benefits

Install accuracy using sleeves, hangers, grids alignment

Consistency with your title blocks and naming

Traceability through transmittals and issue logs

Ready files in PDF, RVT, DWG, IFC, DXF

FAQs for Architectural BIM

Shop drawings are detailed construction ready drawings that show accurate dimensions, materials, connections of various components of a building such as ductwork, piping, plumbing, structural steel, architectural elements. Shop drawing shows how these building components will be manufactured, assembled, installed and constructed.

Shop drawings are usually developed at LOD 350 & LOD 400 depends on requirements, which represent accurate geometry, dimensions, materials, hangers, and connection details ready for manufacturing, installation and construction.

Autodesk Revit, AutoCAD, Navsiworks for modeling and coordination and few more tools like Fabrication CADmep, Advance Steel, Tekla for advanced detailing and fabrication outputs.

Yes, PDF and CAD version of design drawings could be converted into BIM model and shop drawings which could convey design information into detailed, coordinated and construction ready Revit model and shop drawings.

Timelines depend on project size, trade discipline, and complexity. Smaller scopes may take 3-5 working days, mid-size scopes may take 1-2 weeks while large, coordinated MEP or structural packages can take several weeks.

Shop drawings are typically delivered in PDF, Revit (.RVT), AutoCAD (.DWG), IFC, NWC, Bill of material in Excel sheet.