Thursday, 6:12 p.m.

The email lands: “Attaching everything. Need a clean submittals Monday.”

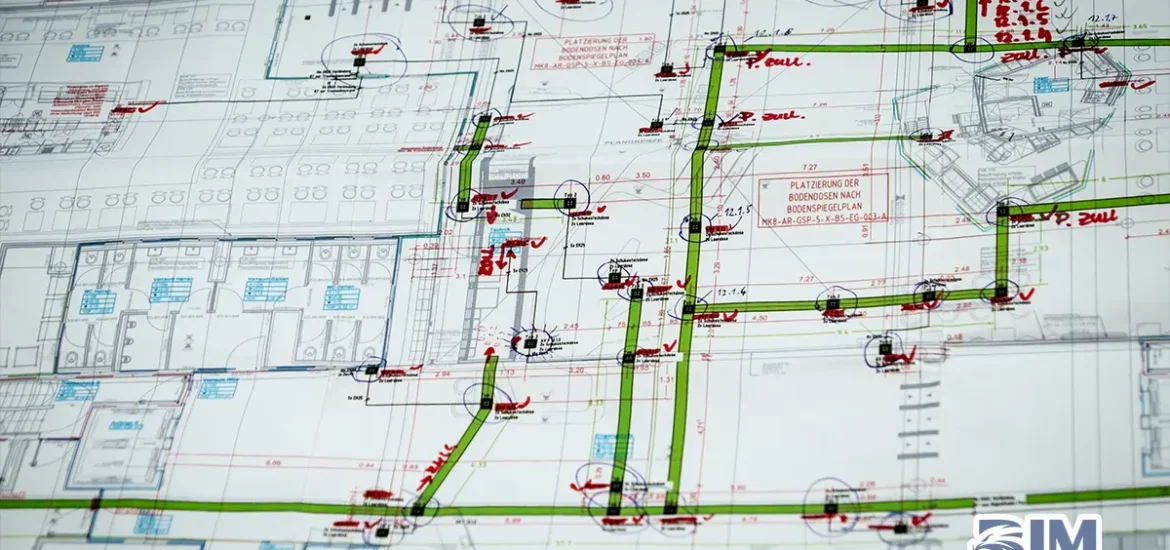

You open the folder. Half the files are scans. Some are sideways. Filenames read like inside jokes. A beautiful elevation is hiding between two crooked spec pages. It feels like someone emptied a shoe box on your desk and said, “Make it a book.”

Most teams panic here. The trick is to stop thinking like a modeler and start thinking like an editor. For the next two days, you are not making drawings—you are making clean submittals. You are making a newspaper. Same look, same order, same truth on every page. When a reviewer flips, their brain stays calm. That calm is what gets you the “approved.” If you want this calm baked into future sets, we set up that rhythm in our Revit Drafting Services.

The newsroom switch

I keep a clean working folder ready, like a newsroom layout waiting for tomorrow’s paper. I drag everything into “Incoming,” look at what I’ve got, and write a one-paragraph note to myself: how many files, which disciplines, what’s obviously broken. Nothing fancy. It gets me out of feelings and into facts.

Then I sort. Architecture with architecture. Structure with structure. MEP with MEP. I don’t rename yet. I just want to see the pile in sensible stacks. If something is scanned, skewed, or unreadable, I put a small dot next to it in my notes. Those dots are tomorrow’s time sinks, not tonight’s.

Before I shut the laptop, I choose one rule for names. Something a human can understand without opening the file. Project, discipline, sheet number, short sheet name, current rev, status. Clean, lowercase, no mystery. I’ll rename in one go tomorrow when my head is fresh.

I sleep.

Friday morning: the plain-English pass

Coffee in hand, I start with names. I open each stack and rename every file so the story reads in the filename itself. Think of it like writing headlines—clean submittals start with filenames that tell the truth. A reviewer should know what they’re about to see before they see it.

When I finish a stack, I copy the filenames into a simple two-column list: file on the left, human sheet title on the right. That list becomes my index at the end.

Next, I fix pages that break trust. I rotate the sideways ones. I deskew the scans so the text stops leaning. If a page won’t print cleanly, I nudge the margins. If a spec is locked inside an image, I run OCR so search will work. I don’t beautify. I remove friction—because clean submittals aren’t about polish, they’re about clarity.

At lunch, I pick one sheet that looks the most “wrong” and turn it into the standard everyone else will follow. I adjust the visible status line so it actually says what the team means. I make sure the current revision is the only story on the page. If a title block is missing half the truth, I add a simple footer band with sheet number, plain sheet name, date, and status. It’s not graphic design. It’s a seatbelt. By the time I’m done with that one sheet, I know exactly how the rest should look.

The afternoon is copy and paste. I give every page the same seatbelt. I don’t chase edge cases. If something is genuinely off, I add a short note to the first page of the set explaining the exception in one line. Reviewers forgive an honest exception faster than a silent inconsistency.

If the scope is headed for fabrication next, this same “newspaper” standard rolls straight into our Shop Drawing Services so fabricators don’t inherit confusion.

Saturday: make it read like a book

Saturday morning, I assemble by discipline. Architecture first, in sheet-number order, then structure, then MEP. Each discipline becomes a small booklet. Then I stitch the booklets into one master. I keep both versions. Reviewers like choice. Some scan the whole set. Some go straight to their stack.

Before lunch, I write the front page. One page. It lists the sheets in plain English, shows the current revision with a short description, states the status of issue, and gives a single contact for each discipline. Clean submittals don’t need cover art—just clarity.

After lunch, I do the flip test. I open the master PDF and flick through like I’m late for a meeting. Two seconds per page. When something snags my eye, I stop and fix it. A rotated plan. A faint key plan. A status line that changed wording mid-set. This “dumb” flip test catches more than any checklist.

Late afternoon, I check the boring things that sink ships. Do file names match the sheet identity? Does the sheet status match the front page? Are we telling one revision story across the set? Clean submittals always tell one story.

By early evening, the set feels like a newspaper. Same voice. Same train tracks. No surprises.

Sunday: short note, calm handoff

Sunday is quiet. I prepare a short cover note. What the set contains. Why we’re issuing it. What changed since the last issue in one line. Who to call for architecture, structure, and MEP. I attach the master, the discipline booklets, and the one-page index. I save a copy of everything in an archive folder with the date so we can prove exactly what left the building.

Sometimes a client wants the same structure to flow into fabrication. That’s when we fold the standard into Shop Drawing Services. If they want the “newspaper mode” to start upstream, we tune their templates as part of Revit Drafting Services so the next submittal starts clean.

Monday, 9:03 a.m.

The reviewer flips the file like a magazine. The index matches the pages. The status is the same everywhere. Revisions tell one story. The filenames help them jump to what they need.

There are still design questions—but there’s no confusion.

“Thanks. This is clear.”

That sentence is what clean submittals in 48 hours are for.